Sarah Cleve

Research activities

Current research topics

My research interest lies in the field of acoustofluidics, more precisely the interaction of (ultra)sound waves with fluids at micro-/millimetric scales.

Acoustic microswimmers

My current work focuses on the understanding and design of artificial, acoustic microswimmers. To this end I am particularly interested in characterizing the microstreaming flows induced by the vibrating swimmer tail, which are responsible for their propulsion. As a first step, we were able to analyze both experimentally and theoretically the streaming induced by a cylindrical tail undergoing elliptical motion.

Acoustic tweezers

I collaborate in several projects involving manipulation with acoustic holograms. In particular, we were able to (i) suppress the rotation of particles trapped in an acoustic vortex tweezer to enable purely translational motion, (ii) pattern miscible liquids (see snapshot) and displace blobs of one miscible liquid within another and (iii) form specific patterns of living cells at the cellular scale.

Past research results

Bubble dynamics

When exciting microbubbles with ultrasound, shape modes can be triggered in certain parameter ranges (of acoustic pressure, frequency and bubble size). We experimentally studied the triggering and temporal evolution of these shape modes. Among others, we were able to observe energy transfers from parametrically excited modes to other non-excited ones, which validated recent non-linear analytical models. Most importantly, I set up an experimental procedure exploiting bubble coalescence in an acoustic trap to entirely control the triggered shape modes by their mode number and axis of symmetry.

(Work conducted at Université de Lyon at LMFA laboratory.)

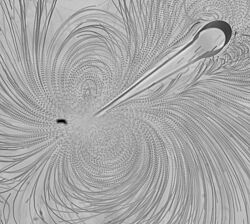

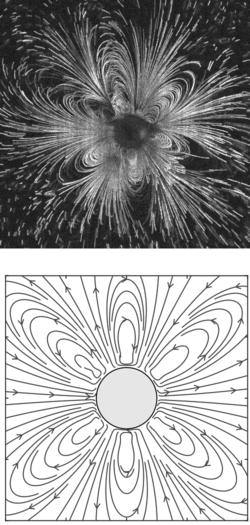

Microstreaming around acoustically excited bubbles

Steady surface oscillations of a bubble in a liquid induce a streaming flow in the vicinity of the bubble. This phenomenon is due to nonlinear viscous effects in the oscillating boundary layer. I was able to experimentally visualize different types of induced streaming patterns, classify them and conclude that characterizing the dominant shape mode is not sufficient to define the resulting pattern. Our new analytical model allowed us to confirm that even seemingly minor contributions to the modal content of the shape oscillations can strongly influence the streaming pattern.

(Work conducted at Université de Lyon at LMFA laboratory.)

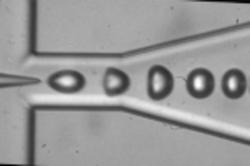

Flow focusing

Microbubbles find current use as contrast agents in medical ultrasound applications. While commercial products usually consist of a large distribution of bubbles sizes it would be beneficial to use monodisperse bubbles. This motivated us to study monodisperse microbubble production via microfluidics, more precisely flow focusing with production rate of about one million bubbles per second, in order to understand today's limits of upscaling this process for industrial processes. An experimental and numerical study allowed us to discuss the role of liquid and gas properties, and achieve a time resolved characterization of the flow fields inside a flow focusing device. Furthermore, we could demonstrate that the production rate and bubble size can be fine-tuned with acoustic actuation.

(Work conducted at University of Twente at Physics of Fluids laboratory.)