Philippe Zinck

Axes de recherche

Catalysis for functional and sustainable polymers

Coordinative Chain Transfer Polymerization (CCTP)

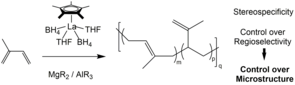

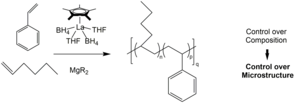

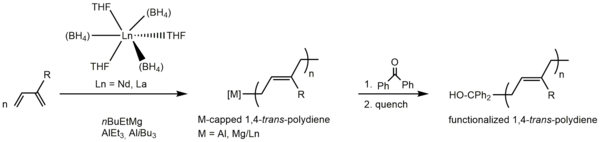

The principle of CCTP is to allow a growing macromolecular chain to transmetallate from a transition metal based catalyst to a main group metal based chain transfer agent. CCTP opens to way to a large array of applications useful for the synthetic chemist that includes not only molecular weight control, atom economy and polymer functionalization, but also the control and design of polymer microstructure. While exploring this fascinating area of polymerization catalysis, we discovered that CCTP affords fine control over the microstructure of polydienes, and that it can be considered as new concept for the control of the composition of statistical copolymers. The concepts were recently extended to the statistical copolymerization of conjugated dienes, to terpolymerizations and to a biobased conjugated diene, myrcene.

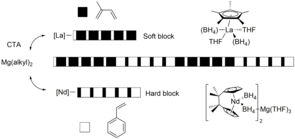

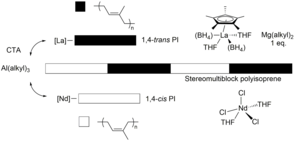

Chain shuttling polymerization

We developped a chain shuttling copolymerization system for the synthesis of a new family of thermoplastic elastomers based on isoprene and styrene. These unique materials exhibit a fully amorphous multiblock microstructure of soft and hard segments. The composition of the blocks and the resulting glass transition temperatures can be easily tuned by changing the feed and/or the relative amount of the catalysts. We further reported a second catalytic combination for isoprene chain shuttling polymerization. The halflanthanocene / dilakylmagnesium catalytic system represented hereafter combined to neodymium trichloride / trialkylaluminum, allows the access to a (1,4-trans / 1,4-cis) stereomultiblock polyisoprene that self-assembles at room temperature.

We have also, in collaboration, hybridized artificial intelligence approaches (artificial neural networks) with Kinetic Monte Carlo (KMC) for mapping the copolymer microstructures reachable by chain shuttling copolymerization, and for inverse polymerization engineering (getting the chemical parameters from the microstructure as input).

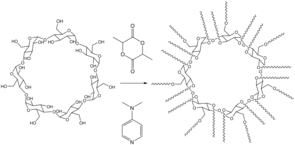

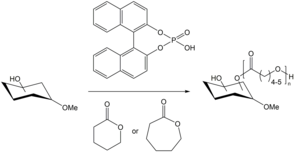

Organocatalysis for polymer carbohydrate conjugates and polylactide end functionalization

Biodegradable polyesters based notably on renewable resources are used in biomedical areas and for consumer goods and packaging applications. Metal mediated polymerizations can lead to the presence of residual metal traces in the material, which can be detrimental for the targeted applications. This can be circumvented by the use of organic molecules as polymerization catalysts.The functionalization of aliphatic polyesters with carbohydrates is an important strategy in this frame to tailor their properties while keeping a biocompatible character. We discovered new reactivities in this field using both well known, readily available and new, home-made organocatalysts for the ring-opening polymerization of cyclic esters. The resulting macromolecular objects have shown promising potential in materials science and pharmaceuticals.

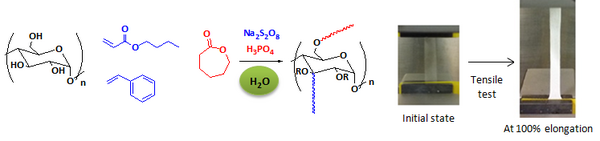

Polysaccharides functionalization and grafting

We have developped mild approaches for the grafting of polymers onto polysaccharides via organocatalytic grafting from approaches in aqueous medium, including access to cellulose and dextran hydroxyesters, as well as a one pot dual functionalization of starch affording highly strechable materials. The grafting of polymer on cellulose nanocrystals lies also in our interests.

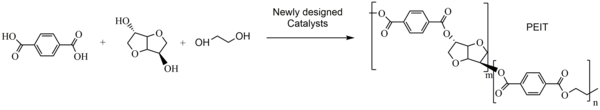

Polycondensation of (new) biobased monomers

We have developped efficient bimetallic catalytic systems based on antimony, germanium and titanium, as well as organocatalysts, for the insertion of isosorbide, a building block derived from starch, into polyethylene terephtalate (PET).

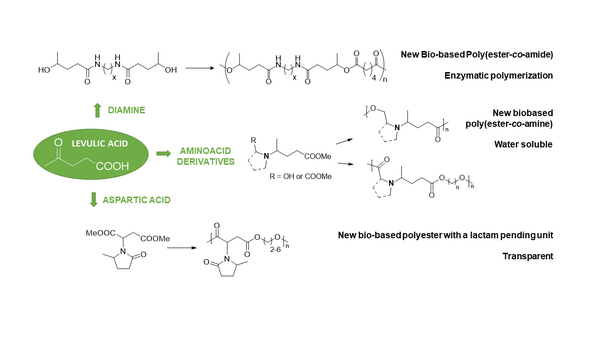

We have designed three libraries of new monomers based on levulinic acid, a promising biobased building block avalaible from the hydrolysis of polysaccharides. The polycondensation of these new monomers lead to new types of specialties polymer, e.g poly(ester-co-amide), poly(ester-co-amine) and polyester bearing a pendant lactam group.